![]() Download HCG Casing Gas Compression

Download HCG Casing Gas Compression

Why Casing Gas Compression?

- Reduce casing pressure, lowering the backpressure on the formation. This will:

- Increase rate of oil production

- Increase overall oil recovery

- No venting –deliver gas to flow line

- Can use gas as fuel or sell it

Casing Gas

- Oil in formations includes natural gas in solution

- For oil to flow into a well, the pressure at the bottom of the well must be less than that of the formation. As oil flows into the well, gas will come out of solution and collect in the casing

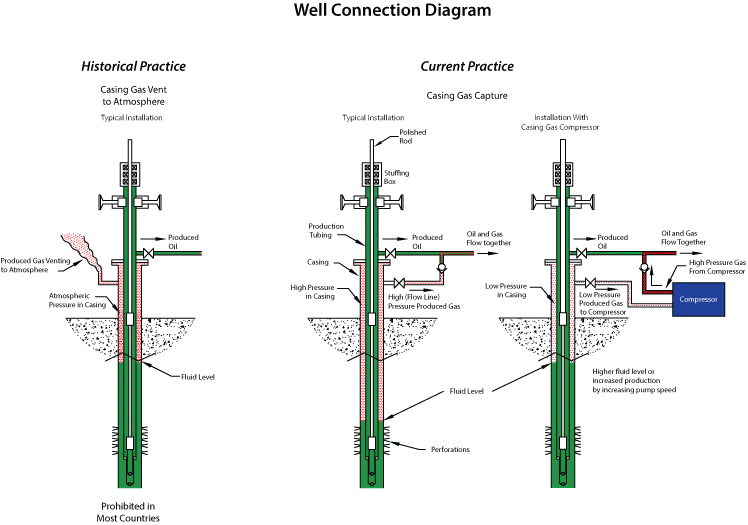

- This gas was traditionally dealt with in one of two ways

- Venting the casing to atmosphere

- Connecting the casing to the flow line

Casing Pressure

Vent to atmosphere- Venting methane to atmosphere is bad for the environment, methane has 25x the greenhouse effect of CO2 (based on 100 year global warming potential)

- Wasting a potentially valuable and finite resource

- This practice is now illegal in many countries for the above reasons

Connect to flow line

- Can reduce well performance due to high backpressure on formation

- Convenient, only 1 pipeline required, gas can be separated from stream and used at battery

What Does Casing Gas Compression Do?

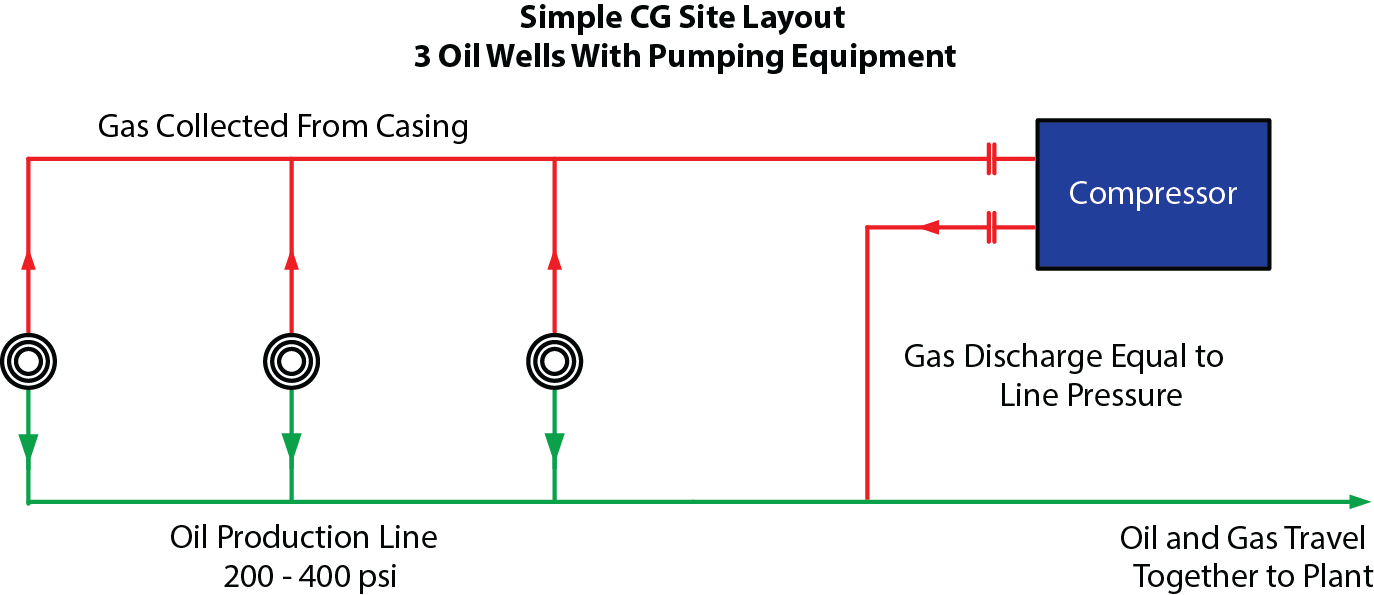

- Reduce pressure in casing, lowering bottom hole pressure

- Differential pressure between the formation and bottom hole is what drives the inflow of oil to the well

- Maximum flow line pressures can reach between 1380-2070 kPa/ 200-300 psi

- A compressor can typically reduce casing pressure to 35-207 kPa/ 5-30 psi, depending on size and gas flow

- Reduction of backpressure against the formation results in higher oil recovery rate

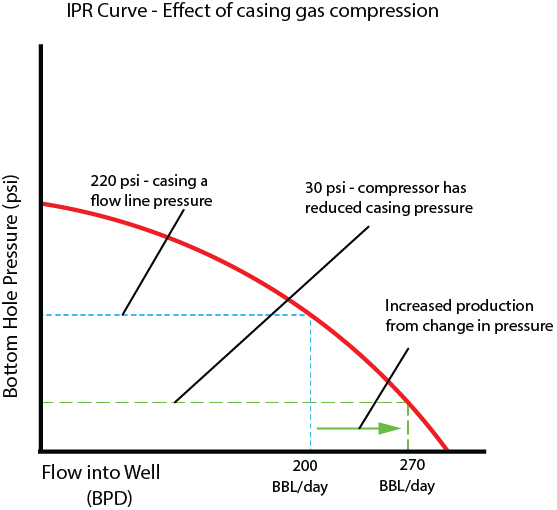

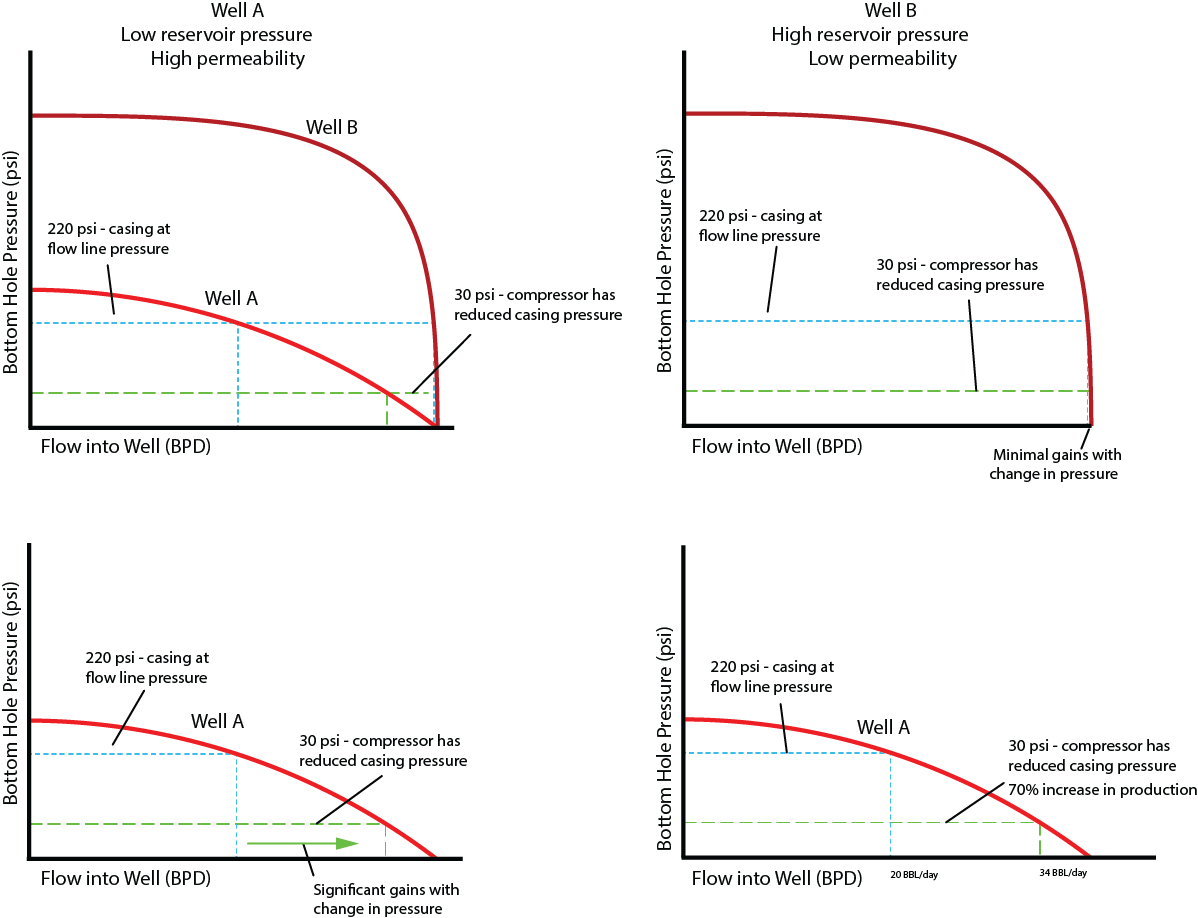

- This effect will be more significant on low pressure formations

- Formation pressure of 20700 kPa(3000 psi), well is 1380 kPa(200 psi), drops to 207 kPa(30 psi), change is 6%

- Formation pressure is 6894 kPa(1000 psi), well is 1380 kPa(200 psi), drops to 207 kPa(30 psi), change is 18%

IPR (Inflow Performance Relationship) Curves

- Indicate change in inflow rates with change of bottom hole pressure

- Essentially, the reservoir’s ability to flow to the well at a range of bottom hole pressures

- Depends on reservoir structure, permeability, pressure, and other factors

- Can be used as a first indicator of a well potentially suited for casing gas compression

Wells Prone to Gas Lock

- Gas lock may occur due to a variety of conditions, such as high GOR, pump spacing, and pump landing location

- A gas locked pump can cause severe equipment damage

- On wells where this is a known issue, a casing gas compressor may aggravate the problem, as lowering downhole pressure will increase the rate of gas breakout

- Potential solutions would be:

- Resetting pump spacing to maximize pump compression ratio

- Adding a gas anchor or other gas separation device to the pump

- Change to a pump designed to handle gas

- Re-landing the pump further below the perforations

- If these do not solve the problem, this well may not be suitable for casing gas compression

- The solution may be to increase head pressure on the pump. This would involve maintaining greater fluid height in the well. Essentially, giving up some amount of production rate in order to avoid gas lock issues.

- Testing is critical, the only way to ensure that a well is suitable for casing gas compression is to test in advance

Testing for Suitability

- Trailer mounted compressors are simple to move around, saving labor and time over testing with a skid mounted unit

- Screw compressors are quite flexible in performance can be adapted to a wide range of operating conditions

- Gas driven, will run off compressed gas, no need for an electrician to hook up power

- A test compressor will determine exactly how a well will respond to casing gas compression, making the economics of the application a certainty rather than speculation

- Can be equipped with a flow meter to precisely determine required size of compressor